Gas Engine Heat Pump (GEHP)

Air to Water Systems

Our eco° Gas Engine Heat Pumps (GEHP) utilise heat exchangers to deliver thermal energy from the GEHP refrigerant (cooling and heating) to fan coil indoor units, air handling units and air handler units. Fuel sources: Natural Gas (NG) and Liquidified Petroleum Gas (LPG)

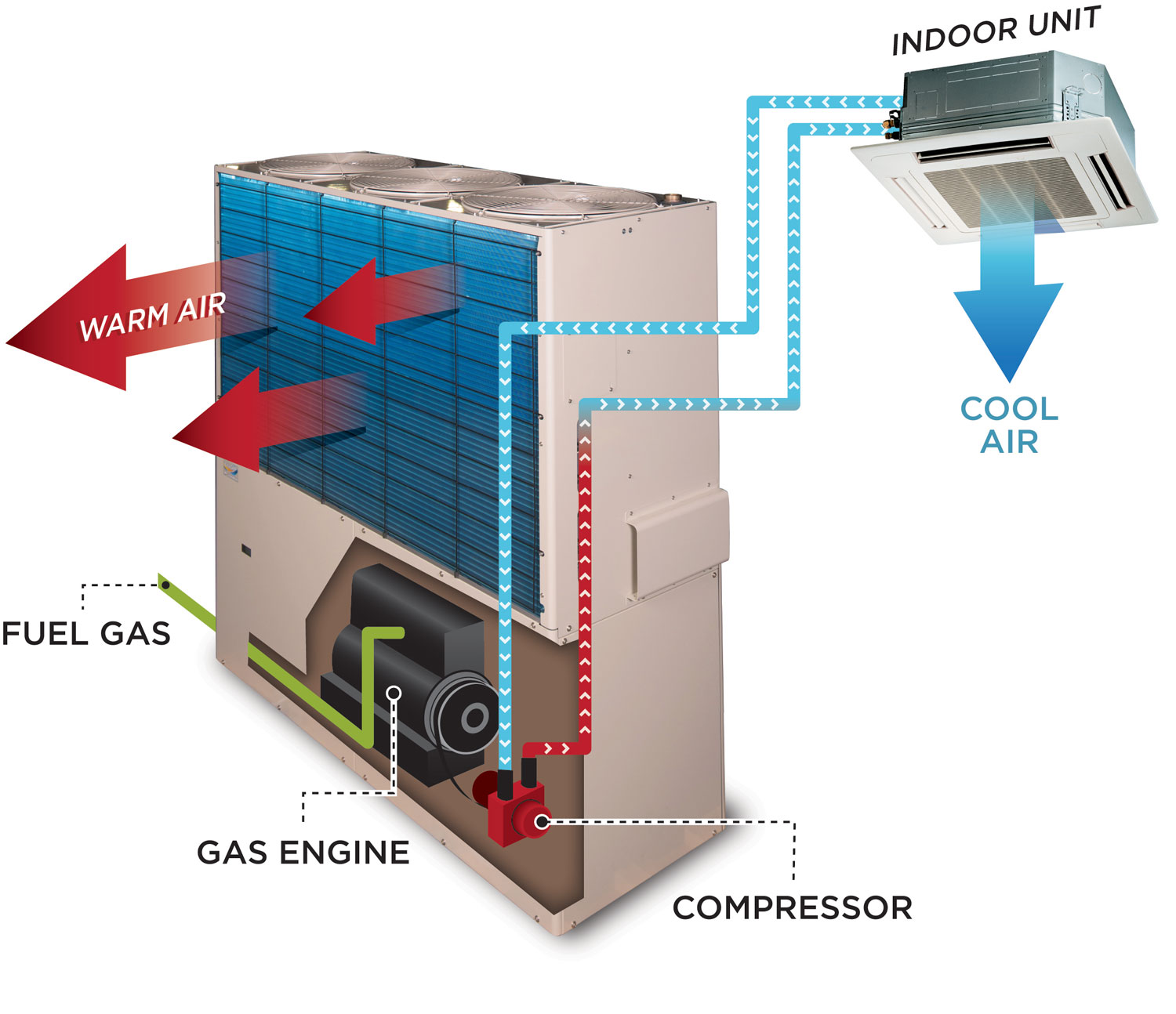

Operating Principle

System Overview

Replacing the conventional electric chiller and boiler configuration, our eco° GEHP can deliver an all-in-one solution for central cooling, heating and hot water production. Our GEHP requires extremely low electrical consumption, no cooling tower and provides direct water connections, allowing for easy installations and low operating costs for a wide range of building applications. Suitable with NG and LPG fuel sources

Air to Water Systems

Gas-Engine Heat Pump (GEHP)

Our air to water solution is available with two simple configuration: direct gas-engine heat pump (GEHP) range or Gas VRF with hydrobox range. Both configurations allow building owners to achieve centralised cooling and heating and hot water production in recovery mode. Explore to learn more

Notable Benefits

Cost Saving Solution

Gas-Engine Heat Pump consumes around 90% less electricity than similar electric air-conditioning system. Where NG & LPG fuel sources are available, Gas Engine Heat Pump offers a tremendous reduction in operating costs for commercial and industrial applications

Notable Benefits

Engine Heat Recovery

Gas-Engine Heat Pump system employs plate heat exchangers to transfer engine heat to the refrigerant cycle, ensuring constant heating output at all times with no defrosting cycle and other common issues face by conventional electric heat pump system

Application

Explore to find common applications for gas absorption and gas engine air conditioning equipment, ranging from residential to commercial to industrial buildings. Specialising in eco-friendly and alternative-fuel energy systems, eco°gbl focuses on delivering high efficiency and low-energy consumptation solutions